STRATOS, the world’s largest DACCS plant is under construction in West Texas (USA)

A new direct air carbon capture and storage plant (DACCS) is under construction in Ector County, Texas that is designed to capture more CO2 from the atmosphere than any other DACCS plant in the world.

The Texas plant, named STRATOS, is being constructed by the large independent oil company Occidental Petroleum Corporation (Oxy) through its wholly-owned subsidiary 1PointFive. The plant was designed by another Oxy subsidiary, Carbon Engineering. The project is overseen by Oxy’s unit, Oxy Low Carbon Ventures.

The plant is expected to begin operating in the second half of 2025. The project has been estimated to more than 1,000 workers during construction and up to 75 workers when the plant is operating.

The plant is designed to capture up to ( ) of CO2 annually, with the potential to expand to 1 million tonnes annually. The captured CO2 will be used for creating marketable carbon credits by storing it underground. The CO2 will also be used in enhanced oil recovery operations or in the manufacture of products such as chemicals and building materials, although creating carbon credits has been the focus in Oxy's presentations.

Oxy's 1PointFive and Carbon Engineering subsidiaries have to deploy 70 industrial-scale direct air capture facilities worldwide by 2035 under current conditions of the carbon credit market. Oxy currently has another 500,000 ton per year DACCS project in design in south Texas, about 600 kilometers southeast of STRATOS.

In addition to being the largest DACCS plant in the world, STRATOS will be only the second industrial-scale DACCS plant to store its captured CO2 underground. The first was Climeworks' Mammoth Project in Iceland that began operation in May 2024. STRATOS' annual capture capacity of 500,000 tonnes will eclipse Mammoth's 36,000-tonne annual capacity.

Prior to Mammoth and STRATOS, CO2 has been stored underground on a large-scale only for CO2 captured from exhaust flues at industrial plants and CO2 used in operations — but not from CO2 captured directly from the air.

The STRATOS plant is located in the middle of the Permian Basin of West Texas, one of the most prolific oil and gas producing areas in the world. Oxy has been one of the leading producers in the basin for decades, and is the commercial purchaser and injector of CO2 for enhanced oil recovery in the basin. The location is near existing acreage and infrastructure of Oxy's oil field operations.

The STRATOS plant will enable Oxy to draw on its more than 50 years of experience handling CO2. Other economic drivers include a high demand for carbon credits that the plant will create (see discussion below) and a federal tax credit.

STRATOS' CO2 Capture and Concentration Process

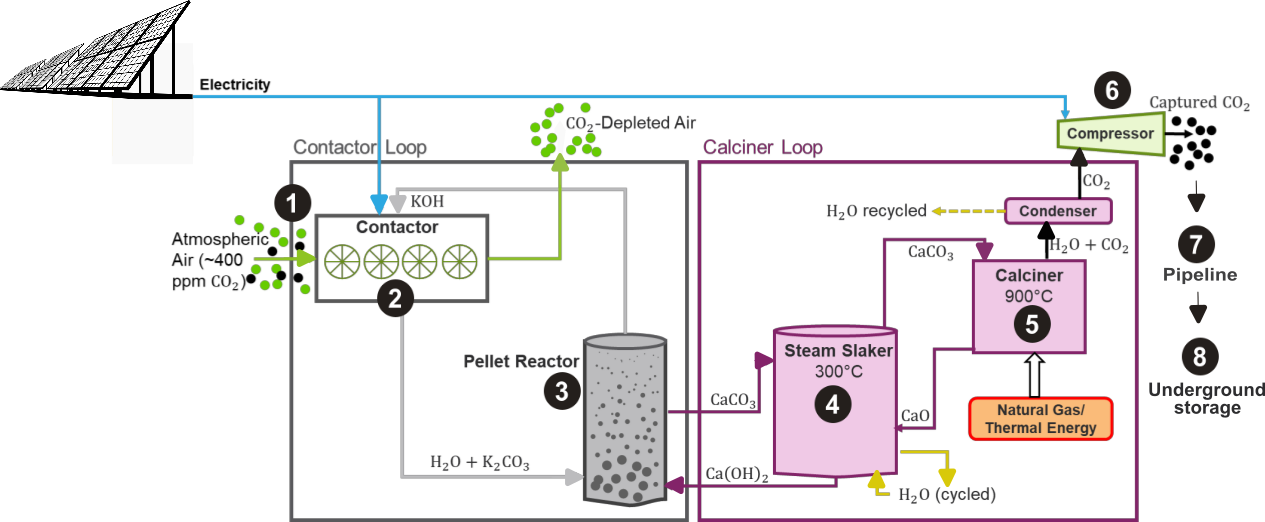

The plant will use a liquid sorbent in the capture process, rather than a solid sorbent as used in some DAC plants. A sorbent is a chemical compound that binds to CO2 molecules, enabling them to be pulled out of the air. The CO2 capture-to-underground storage has eight basic steps, as shown in the figure below and as summarized in the following table.

| Step | Process | Description |

|---|---|---|

| Capture CO2 from air. | Industrial fans pull air into the plant for processing. | |

| Separate CO2 from air in contactor. | The air flows through a contactor system, passing over the liquid sorbent, a water/potassium hydroxide (KOH) solution, which binds to the CO2 molecules, separating the CO2 from air and forms a potassium carbonate (K2CO3) solution. | |

| Concentrate CO2 in pellet reactor. | The potassium carbonate (K2CO3) reacts with calcium hydroxide (Ca(OH)2)to form small pellets of calcium carbonate (CaCO3) and potassium hydroxide (KOH) that is reused in the contactors. | |

| Dry and warm pellets in slaker. | The calcium carbona/te (CaCO3) pellets are heated to 300o C in a steam slaker. | |

| Release CO2 gas from pellets by heating in a calciner (a type of industrial furnace). | The calcium carbonate (CaCO3) pellets are heated to 900o C in a natural-gas fired calciner, releasing a 90% stream of CO2 gas and quicklime (calcium oxide, CaO) The quicklime returns to the slaker where steam converts it back to calcium hydroxide (Ca(OH)2) for reuse in the pellet reactor. | |

| Compress CO2 gas to super-critical state. | The concentrated stream of CO2 gas is compressed to a highly fluid, liquid-like (super-critical) state. | |

| Pipeline super-critical CO2 to injection wells. | The super-critical CO2 flows into a pipeline that extends from the DAC plant to underground injection wells. | |

| Inject super-critical CO2 underground. | The super-critical CO2 flows down the steel casing inside the injection wells to the sedimentary rock layer where it remains stored. |

Oxy has long-established businesses as a distributor of potassium hydroxide (used as the sorbent in the contactor) and as a producer of natural gas (the fuel used to heat the calciner). The chemical division of Oxy, Oxychem, is the largest distributor of potassium hydroxide in the US and second in the world. Potassium hydroxide, calcium hydroxide (used in the pellet reactor), and water are recycled in the plant for reuse. CO2 produced from natural gas combustion in the calciner will be captured and added to the CO2 stream for storage.

CO2 Injection and Storage

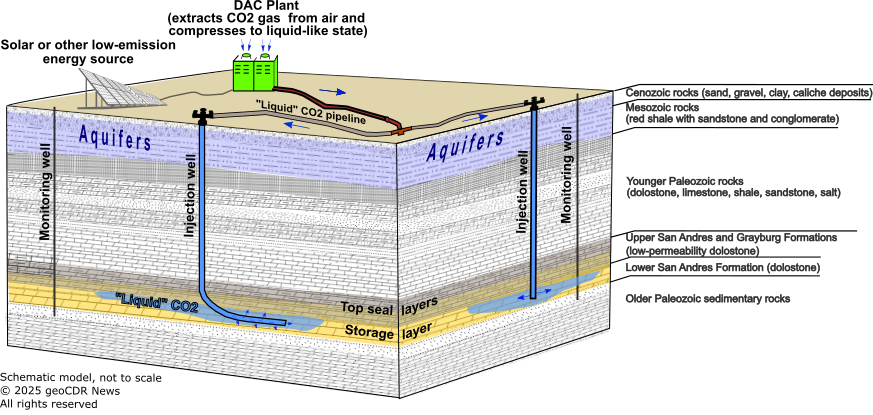

Oxy has received a permit from the state regulator, the Texas Railroad Commission, to construct a 4-km long pipeline for transporting the liquid-like CO2 from the STRATOS plant to injection wells located near Penwell, TX.

The company also has received permits from the U.S. Environmental Protection Agency (EPA) for drilling three injection wells. The permit applications indicate CO2 will be injected into the Lower San Andres Formation, a layer of 'dolostone' that lies about 1,300 meters below the land surface. EPA approved the injection well permit applications in April 2025.

Dolostone is a common sedimentary rock composed of the mineral dolomite (MgCaCO3). Dolostone is similar to limestone (composed of the mineral calcite, CaCO3), but with a higher magnesium (Mg) content. CO2 can be stored inside tiny pore spaces in dolostone. The pore spaces are between grains in the rock such as ooids, which are a type of rounded grain deposited along the coast of a warm sea.

Storage of fluid CO2 in pore spaces inside sedimentary rock undergound is distinguished from storage underground by 'carbon mineralization' which results when liquid-like CO2 is injected and chemically reacts with basalt (CaMgO6Si2) or similar igneous rock to form a solid limestone (CaCO3) type of rock. The previously mentioned Climeworks' Mammoth Project in Iceland stores CO2 by carbon mineralization in basalt (a volcanic igneous rock), the most widespread rock type in Iceland. The Mammoth Project can be classified as direct air capture with carbon mineralization storage (DACCM), in contrast to STRATOS' direct air capture with pore space storage (DACPS).

One of the three injection wells in the STRATOS project will have a horizontal "leg" drilled horizontally about 1,400 meters extending out from the vertical portion of the well through the nearly flat-lying Lower San Andres Formation. A horizontal wellbore increases distribution of injected CO2 in a rock layer, compared to a vertical wellbore.

Oxy’s EPA well permit identifies two topseal layers for the injected CO2 as the Upper San Andres Formation and the Grayburg Formation which overlie the Lower San Andres Formation. A low topseal layer is necessary for preventing vertical migration of the injected CO2. All three geologic formations produce oil and gas in several fields in Ector County and in the greater Permian Basin. and permeability in the formations vary depending on geographic location.

Horizontal and vertical CO2 injection wells at STRATOS (conceptualization)

Underground injection of CO2 and storage will be conducted under an EPA-approved Monitoring, Reporting, and Verification (MRV) plan, along with a from Oxy warranting performance during the life of the project, including final well plugging and monitoring.

For underground storage wells, “permanent” storage is confirmed by project monitoring data conducted for a minimum of or other period if approved by EPA.

As part of the injection well permitting process, EPA reviewed the adequacy of Oxy's plan for preventing leakage of stored CO2 from either well casings or through the topseal layer overlying the underground injection layer.

Energy Consumption

STRATOS will use electricity for powering fans, the contactor air separation units, pumps, and compressors. The electricity will be generated from to be provided by Origis Energy, a privately held renewable energy producer. Natural gas will heat the calciner (the industrial furnace that heats the CaCO3 pellets to release the concentrated CO2).

The STRATOS plant is based on Carbon Engineering's design. The energy use of a plant using the design has been to consume 6.6 of energy per tonne of CO2 captured. About 80% of the energy use is from burning natural gas to heat the calciner and 20% is electricity that powers the plant.

On an annual basis, STRATOS can be estimated to consume 3,300,000 gigajoules of energy (500,000 tonnes captured, multiplied by 6.6 gigjoules per tonne captured). This amount of energy is equivalent to the amount of energy consumed by 78,000 households in one year (assuming one household consumes 42 gigajoules per year as indicated in a of the International Energy Agency).

Negative CO2 Emissions

Two key questions about any CDR project are:

- How much CO2 does the project permanently remove from the atmosphere?

- Is the project ?

STRATOS is designed to remove up to 500,000 tonnes of CO2 from the atmosphere per year. Putting that figure in perspective, Vicki Hollub, CEO of Oxy, has pointed out that "would represent the CO2 that's equivalent to taking off the road."

The question of whether a project like STRATOS will be carbon negative has been addressed at least theoretically by the U. S. Department of Energy. Their analysis estimated a system similar to STRATOS would permanently remove about from the atmosphere for each tonne of CO2 captured from the atmosphere and, therefore, would be carbon negative. STRATOS' carbon capture would not be carbon negative if the captured CO2 is used for enhanced oil recovery, or if the plant is powered by fossil fuels whose emissions are not captured and stored.

Project Financing

Oxy is funding the estimated along with joint venture partner, BlackRock Inc., who is through a fund managed by its Diversified Infrastructure business. Prominent investor Warren Buffett has been a major Oxy stockholder since 2022.

When the plant is operating, revenue will come from the sale of carbon credits and CO2 for use in products. Additional revenue will come from a federal tax credit provided in Section 45Q of the U.S. Internal Revenue Service Tax Code. The tax credit is available for a maximum of 12 years for of CO2 captured and permanently stored.

Sale of DAC-Generated Carbon Credits and Cost of DAC

Several companies have completed carbon credit with Oxy for credits that will be generated by STRATOS, including: AT&T, Microsoft, Amazon, Airbus, All Nippon Airways (ANA), TD Bank Group, and the professional sports teams the Houston Astros and Houston Texans. SK Trading International completed an to purchase “net-zero” oil from Oxy, that is, oil offset by CO2 captured and stored at the STRATOS plant.

Although companies generally are not required by law to buy carbon credits to offset their carbon emissions, they are motivated to buy credits in order to meet any net-zero emissions commitments they have made.

Carbon credit prices in the agreements have not been disclosed, but may be in the range of $400 to $630 (USD) per tonne as indicated in Oxy's for STRATOS. The value of the federal 45Q tax credit is shown as $180 (USD) per tonne, indicating a focus on permanently storing CO2 captured at Stratos, rather than using the CO2 in traditional enhanced oil recovery operations which earn a tax credit of $130. The assumption for the cost of capturing and storing CO2 is shown as $400 to $500 (USD) per tonne.

Demand for DAC-generated carbon credits appears to be brisk and is expected to grow. Richard A. Jackson, Oxy’s President of Operations, U.S. Onshore Resources and Carbon Management, said during Oxy's on November 8, 2023, “In a scenario where the cost of capture remains at $450 (USD) per tonne, we still expect the market for DAC-generated CDRs to be significantly undersupplied. Demand for CDR credits from the aviation industry is expected to reach an inflection point in 2027 when the International Civil Aviation Organization begins requiring airlines to reduce or offset their annual emissions through the Carbon Offsetting and Reduction Scheme for International Aviation, also known as CORSIA.”

As of late 2023, much of STRATOS' future carbon credits were already sold for several years out. "STRATOS’ net capacity is sold out to about 65% to 70% to 2030. And then there's a strong pipeline behind that of earlier stage negotiations that's also growing that takes us up to about 85% net capacity sold out to 2030.", said Michael Avery, President and General Manager of Oxy's subsidiary 1PointFive, in the

Criticisms

A general of many carbon dioxide removal projects is that in society's effort to achieve net zero emissons, it would be more energy and cost efficient to replace fossil fuels very soon with renewable energy sources such as solar and wind, than to continue burning fossil fuels and developing complex systems such as DACCS for capturing and storing the resulting CO2 emissions.

Oxy's rationale for pursuing industrial-scale DAC as a commercial enterpise is spelled out in its 2023 document "Oxy's Positions on Climate-Related Policies". The document says the company endorses the goals of the Paris agreement to limit the global temperature increase in this century to 2 degrees Celsius above preindustrial levels, and recognizes society's need to reduce emissions.

The positions document says Oxy is focusing its "efforts on the design of proposed policies seeking to advance technological solutions that can deliver significant rapid reductions in current CO2 emissions and atmospheric CO2 concentrations by using existing infrastructure while continuing to supply consumers with affordable, reliable energy sources and essential products." It goes on to say, " and DAC will remain essential over the long term for hard-to-abate emissions, to address elevated concentrations of atmospheric CO2, and to provide CO2 for low-carbon or net-zero fuels and feedstocks."

A further aimed specifically at the development of DACCS technology by oil companies is that DACCS-generated carbon credits are only a distraction from actually reducing the use of oil and gas, and carbon credits prolong the lives of oil- and gas-producing companies.

Oxy has acknowledged the potential for DACCS technology to prolong the life of the oil and gas production industry. Oxy CEO, Vicki Hollub, said at an investment in 2023, referring to Oxy offsetting its oil and gas production with DACCS-generated credits, "If we could get the entire [oil and gas] industry to do that, there would be no reason to shut down oil and gas development — and it really could and should continue for the next 60, 70, or 80 years."

But there is at least one opinion that basic economics will prevent DACCS-generated carbon credits from significantly prolonging the lives of traditional oil and gas companies. This opinion comes from David Keith, founder of Carbon Engineering who developed STRATOS' DAC technology. His view is that the cost of permanent carbon removal will remain above $150 (USD) per tonne for at least a few decades—a penalty of around $70 per barrel of oil, based on an oil price of $80 per barrel.

"Though it may provide a green aura, an oil company’s carbon-removal business, however successful, will not protect its legacy oil business from strong carbon prices and policies," Keith said in a 2023 opinion piece published in magazine. "Neither greenwashing nor green reality changes the fundamentals."