Equipment malfunctions at CCS sites in Norway and U.S. underscore need for robust monitoring, reporting, and verification in carbon storage underground

Two incidents at prominent carbon capture and storage (CCS) projects — in Norway’s Sleipner gas field and at Archer Daniels Midland’s (ADM) Decatur corn-ethanol plant in Illinois (USA) — have highlighted challenges in accurately accounting for and securing stored CO2. Both incidents involved equipment malfunctions. Together, they underscore the need for transparent monitoring, rigorous measurement protocols, and regulatory oversight as CCS, DACPS, and DACCM projects scale up for industries' climate mitigation efforts.

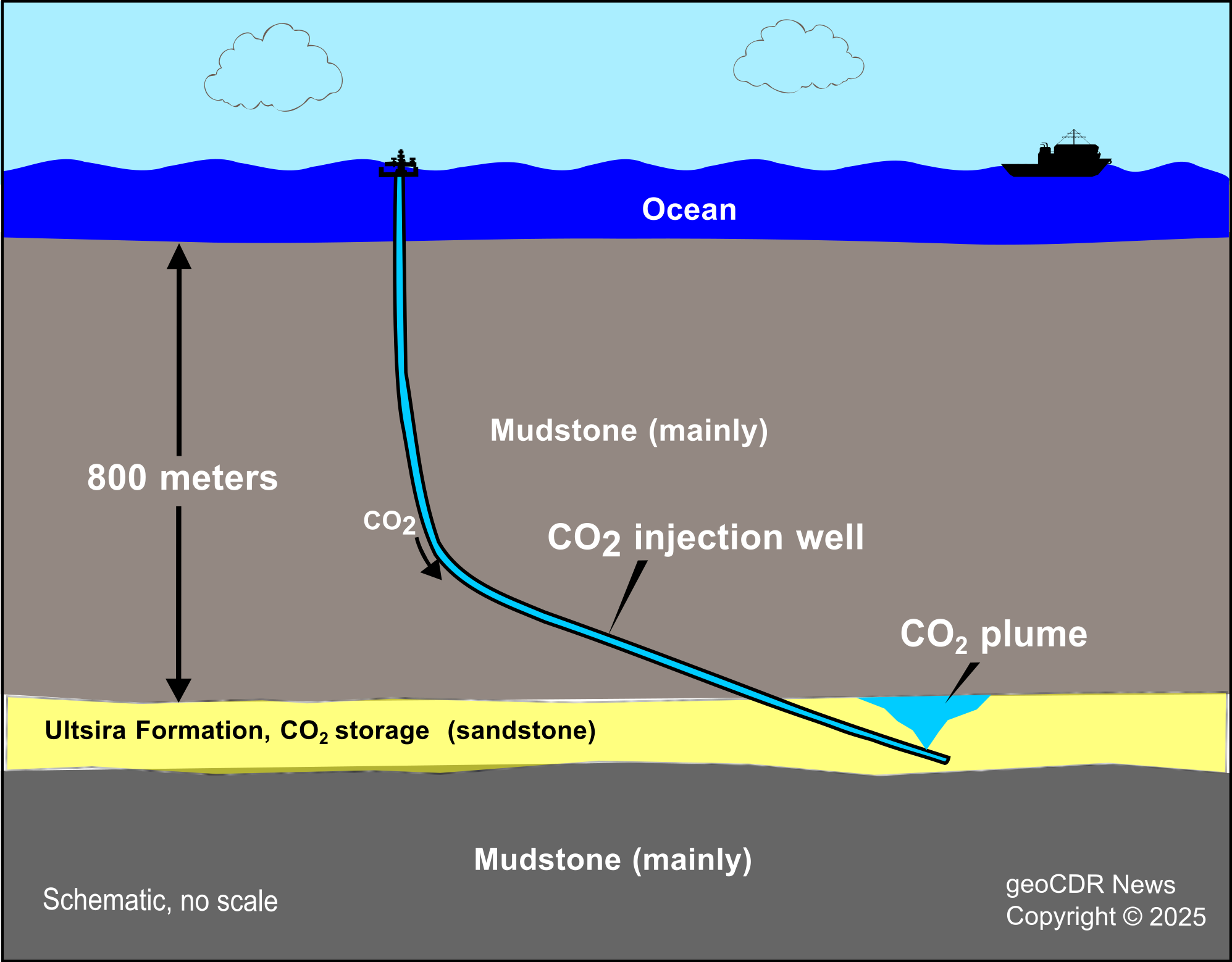

At Norway's Sleipner gas field, operated by Equinor and in operation since 1996, the company reported in 2021 that a malfunctioning flow transmitter led to the company's over-reporting of CO2 injection volumes during the period 2017 through 2021. The amount of CO2 that was over-reported was more than 500,000 tonnes or about 30% of the injection total, as estimated by the investigative journalism organization DeSmog whose analysis compared figures in several years of Equinor's reports.

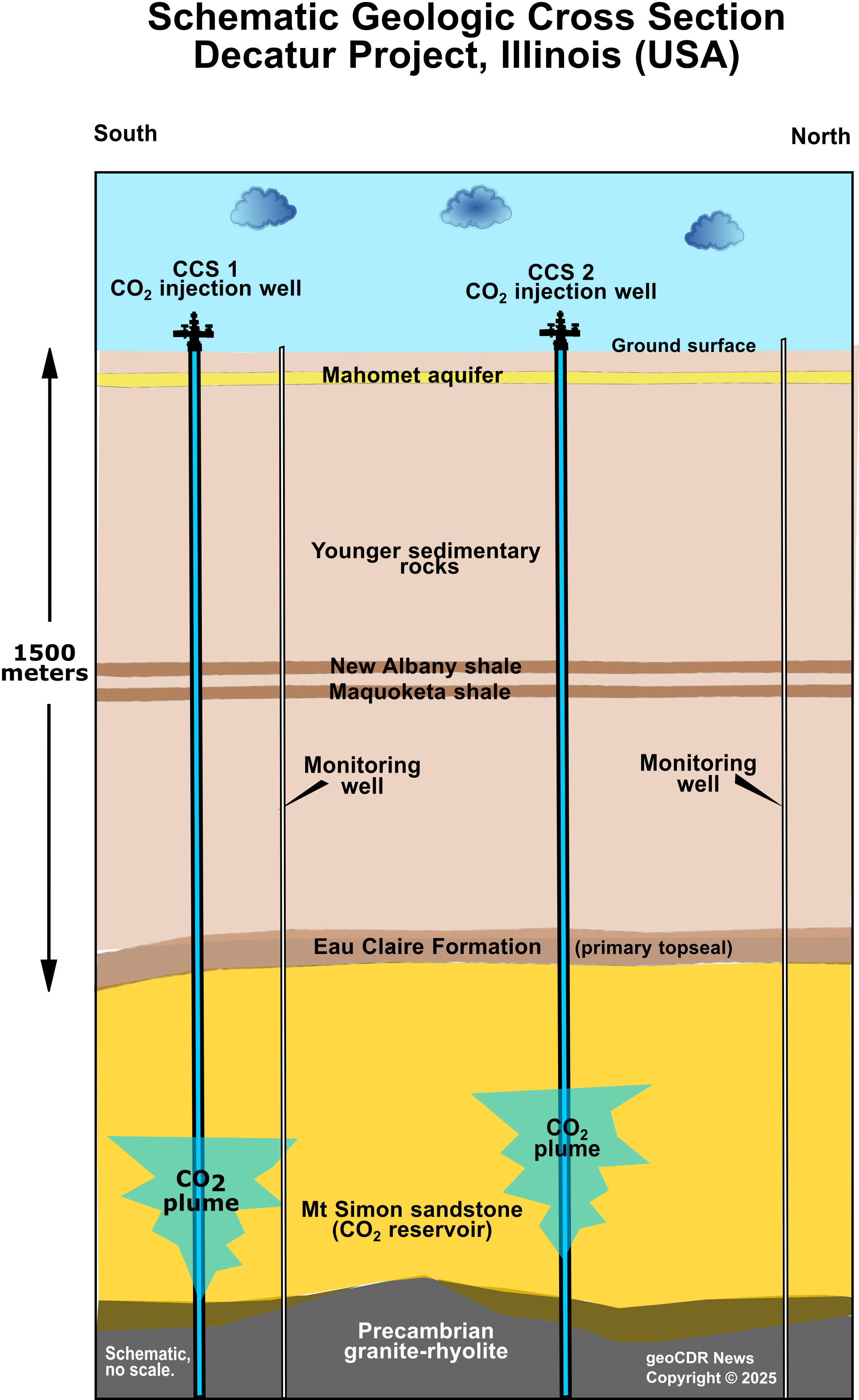

More recently, in the United States, Archer-Daniels-Midland Company's (ADM) Illinois Industrial Carbon Capture and Storage (ICCS) project reported in 2024 that its injected CO2 had to an "unauthorized" formation (Ironton-Galesville) which directly overlies the caprock formation (Eau Claire formation). The Eau Claire formation is the topseal overlying the CO2 storage reservoir, the Mt. Simon Sandstone.

The leaked CO2 was believed to have not reached overlying aquifers.

The leaks resulted from corrosion in small-diameter steel tubing inside the monitoring wells that extends from the ground surface down to the formations. The U.S. Environmental Protection Agency issued an Administrative which documents a violation of the Clean Water Act and requires ADM to complete various remedial measures to address the leaking monitoring well.

Whatever lessons are learned about maintaining equipment in the CCS operations at Sleipner and Decatur will apply as well to the geologic CDR methods of DACPS (direct air capture with storage in pore space underground) and DACCM (direct air capture with carbon mineralization storage).

As global deployment of carbon removal and storage technologies accelerate — driven by net-zero commitments and financial incentives — project developers are likely to face increasing scrutiny from regulators, investors, and the public. These incidents illustrate that achieving durable climate benefits requires not only technological sophistication but sustained diligence in measurement, verification, and permit compliance.