Italian OAE developer, Limenet, joins Carbon Business Council and forges ahead with new plant and working capital

Limenet, an Italian climate tech start-up focused on ocean alkalinity enhancement (OAE), recently announced in a LinkedIn post that it has become a member of the Carbon Business Council — a nonprofit trade association uniting companies working to restore the climate.

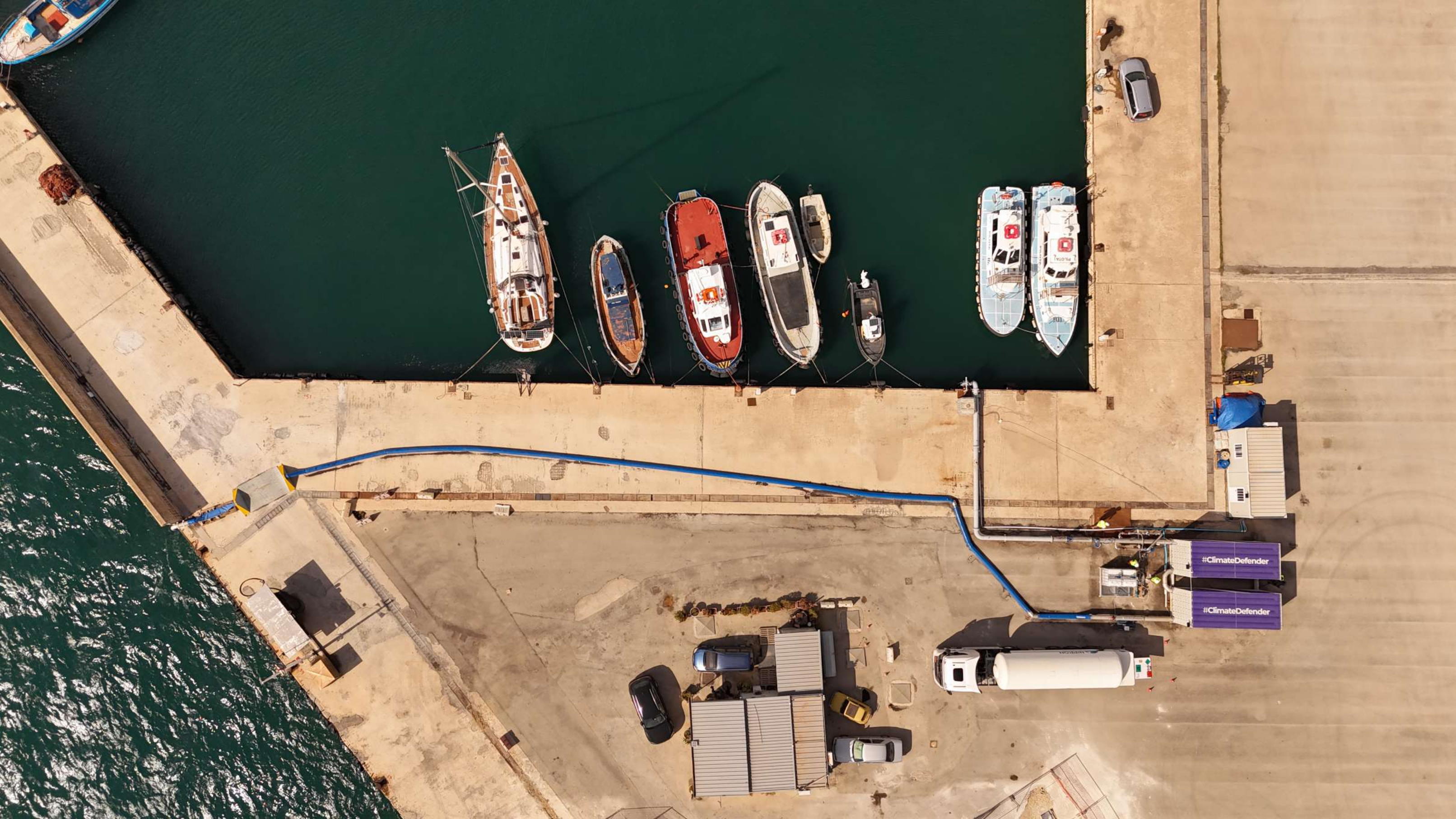

This membership is the latest milestone in Limenet’s push to establish itself as a leader in ocean-based carbon removal using its patented process. In September 2024, the company launched its first modular carbon dioxide removal facility in Augusta, Sicily, a major step toward scaling up ocean carbon storage. The plant converts atmospheric CO2 into stable calcium bicarbonate (Ca(HCO3)2) dissolved in seawater and is designed to process up to 100 kilograms of CO2 per hour.

Adding to its credentials, Limenet recently secured ISO 14064-2 certification from RINA, an international standards body, for its carbon removal methodology. This recognition places the company among a small group of firms globally whose processes meet rigorous verification standards.

Limenet is a "benefit corporation". A "benefit corporation" in Italy is a for-profit business structure that legally commits to pursuing both profit and a positive impact on society and the environment, alongside its financial goals. Limenet was founded in 2023 by Stefano Cappello, along with co-founders Giovanni Cappello (Stefano's uncle), Enrico Noseda, and Valdis Bisters. The company emerged from a research project that Giovanni Cappello participated in, the Desarc-Maresanus project. That project focuses on removal of atmospheric CO2 through increased alkalinity of the sea. The project is a collaboration between Politecnico di Milano (the largest public technical university in Italy) and the Foundation Euro-Mediterranean Center on Climate Change, with funding from Amundi (one of Europe's largest investment management firms) and others.

How Limenet’s Process Works

Unlike other OAE projects that use crushed basalt or other igneous silicate rocks to increase seawater alkalinity, Limenet relies on sedimentary limestone (calcium carbonate, CaCO3) as its feedstock. While basalt is typically ground to a fine-grained powder and dispersed directly into the ocean, limestone undergoes two transformation steps before release to the ocean.

First, the limestone (CaCO3) is crushed and heated in a kiln in a process called calcination. This reaction removes carbon dioxide (CO2) and produces quicklime (calcium oxide, CaO), a highly reactive material. The CO2 released in this stage is not vented to the atmosphere, but is captured for conversion to calcium bicarbonate later in the process.

Next comes slaking: the quicklime (CaO) is mixed with water (H2O) to form calcium hydroxide (Ca(OH)2). About half of this calcium hydroxide is then exposed to ambient air, where it reacts with atmospheric CO2 to form calcium bicarbonate (Ca(HCO3)2).

The remaining portion of calcium hydroxide is combined in a reactor tank with seawater and the CO2 collected from two sources: CO2 emissions released during calcination and CO2 generated from the combustion of fuel (biomass in Limenet's design) used to heat the kiln. This mixture of calcium hydroxide (Ca(OH)2), water (h1O), and CO2 also forms calcium bicarbonate (Ca(HCO3)2).

As a final step, both streams of calcium bicarbonate — from the calcium hydroxide air reaction and from the reactor tank — are discharged into the ocean. There, the calcium bicarbonate increases seawater alkalinity, raising pH and enhancing the ocean’s ability to absorb additional CO2 from the atmosphere. Because calcium bicarbonate is highly stable, it can persist in ocean waters for millennia, effectively locking away the carbon permanently.

Limestone offers an advantage over basalt as a feedstock in OAE because it dissolves more readily in water, speeding the process of ocean water absorbing CO2 from the atmosphere. However, limestone requires more energy to prepare, due to the calcination step. Limestone contains fewer trace metals than basalt such as chromium and molybdenum which could adversely impact sea life if added to seawater in large amounts.

Verification of the amount of carbon removed in an OAE project using limestone may be easier than using basalt, because — at least in Limenet's approach — bicarbonate (as calcium bicarbonate) is directly discharged to the ocean, and is an indicator of the amount of CO2 removed in the process. Spreading crushed basalt in the ocean requires measuring how much bicarbonate forms in the ocean water from dissolution of basalt grains — a more inexact measurement than measuring how much bicarbonate is directly discharged into the ocean.

Funding and Carbon Credit Sales

In September 2024, Limenet announced at a conference in Milan that it had raised €5 million in new capital to expand its operations and scale CO2 removal capacity to 2,000 tonnes annually by 2025. This follows over €2 million in previous seed funding. The additional resources will support building a modular facility designed to capture, process, and store carbon at larger volumes.

At the same event, the company unveiled its first commercial agreement: a sale of 1,000 verified carbon credits to KlimaDAO, a prominent carbon credit marketplace.

“This is just the beginning,” said Limenet CEO Stefano Cappello. “We’ve proven that our approach works, and with new funding, we’re ready to accelerate our contribution to global decarbonization.”

By combining established industrial chemistry with innovative carbon management, Limenet hopes to help oceans play a much larger role in safely removing carbon dioxide from the atmosphere — and to inspire broader adoption of ocean alkalinity enhancement as a practical climate solution.