Feasibility study of nuclear-powered completed

A direct air capture (DAC) plant uses a lot of heat energy to separate CO2 from air. And a nuclear power plant throws off a lot of excess heat while generating electricity.

So, why not marry the two, and have a nuclear power plant send its waste heat to a DAC plant?

That is what the U.S. Department of Energy (DOE) considered in a feasibility study that was completed in 2024.

The nuclear power plant in the study is Southern Company’s Joseph M. Farley nuclear power plant located about 300 km southwest of Atlanta, Georgia near Dothan, Alabama in the southeastern United States. The Farley nuclear plant produces 2,775 megawatts of thermal energy to generate 1,776 megawatts of electricity — enough electricity to supply about 450,000 homes.

The feasibility study included storing the captured CO2 underground in pore space in sandstone layers, thus making the DAC project a DACPS (direct air carbon capture with pore space storage) project.

Farley Nuclear Power Plant Operation

The Farley nuclear plant has been running since the 1970s — heating water pumped from the nearby Chattahoochee River to make steam that turns the blades in a turbine which spins a magnet in a wire coil (a generator) to make electricity.

After the steam exits the turbine, it is cooled in a condenser and the water is returned to cool the reactor. Excess heat in the condenser is vented to the atmosphere from large cooling towers, creating the visible mist commonly seen above power plant cooling towers. It is this excess heat that the DOE-funded feasibility study is considering for use in a direct air capture plant.

DOE Farley DACCS study

The Farley project is one of several projects DOE has funded for studying the feasibility of using industrial waste heat for powering a DAC plant. Waste heat from nuclear reactors has been used in various industrial applications worldwide including water desalination, oil refining, biomass-based oil production, and district heating.

The Farley study estimated system costs, performance, and identified business-case options for using thermal energy in the DAC plant. The study assumed electricity generated by one of the two units of the nuclear power plant the DAC plant will power the DAC plant's air fans, CO2 compressor, and other components.

Battelle Memorial Institute (Columbus, Ohio) led the overall feasibility study, evaluating a DAC system designed by AirCapture LLC of Berkeley, California. DOE awarded a grant of $2,499,167 to the project team. Funding from the team of $908,850 brought total funding to a total of $3,408,017.

DAC plant in Farley study

The DAC system in the Farley study was designed to capture at least 5,000 (and potentially up to 20,000) net tonnes of carbon dioxide (CO2) per year from ambient air — making it a pilot-scale DAC plant, in comparison to an industrial-scale plant that would capture tens to hundreds of thousands of tonnes of CO2 per year. The world’s first industrial-scale DAC plants are only in the design and construction phases of development.

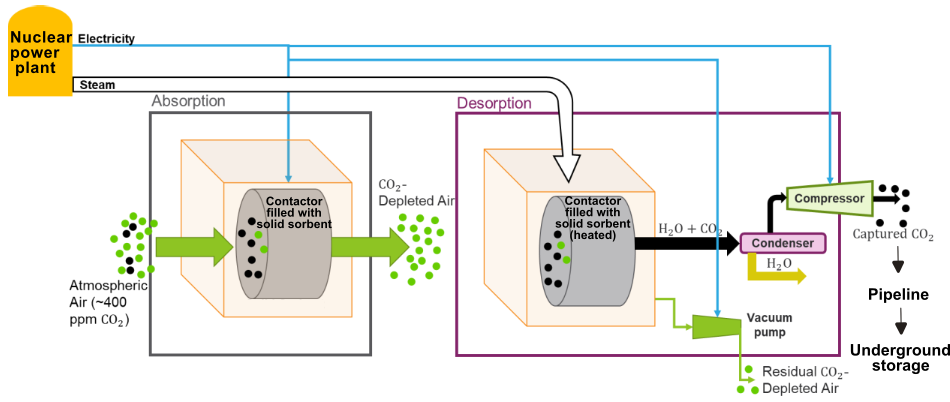

In DAC plants like the one in the Farley study, there is an "absorption step" followed by a "desorption step" (see process diagram below). In the absorption step, fans bring atmospheric air into the plant where it passes over a contactor structure that is filled with a solid chemical sorbent (in this case a polymeric amine). The sorbent grabs (absorbs) CO2 molecules from the passing air. The “cleaned” air is vented back to the atmosphere, leaving the captured CO2 attached to the sorbent in the contactor.

Source: U.S. Dept. of Energy, with labels modified by geoCDR News.

To release (or "desorb") the captured CO2 from the sorbent, the sorbent is heated to about 150oC. This produces a concentrated stream of CO2 gas being released from the sorbent. The CO2 gas is then compressed to a liquid-like (super-critical) state for transport to underground storage by pipeline.

The sorbent is reused in the DAC plant after further heating to remove moisture.

The large amount of heat used in heating the sorbent to 150oC in the desorption process is what could make it advantageous to use waste steam heat from the nuclear plant. The DAC plant was estimated it will use of steam to capture 1 tonne of CO2.

The study included a lifecycle analysis that estimated powering the DAC plant with the nuclear plant's electricity and waste heat would have net carbon removal efficiency of 92.5%, making the DAC plant's operation carbon negative (removing more CO2 than it produces).

Cost estimates for construction and plant operation were not included in the study's final summary that was published in 2024. The summary does say that financing would be hard to obtain for the hypothetical project due to its high cost and low capacity. Also, tax credits such as 45Q and carbon credit sales would be needed for making the project feasible.

CO2 underground storage

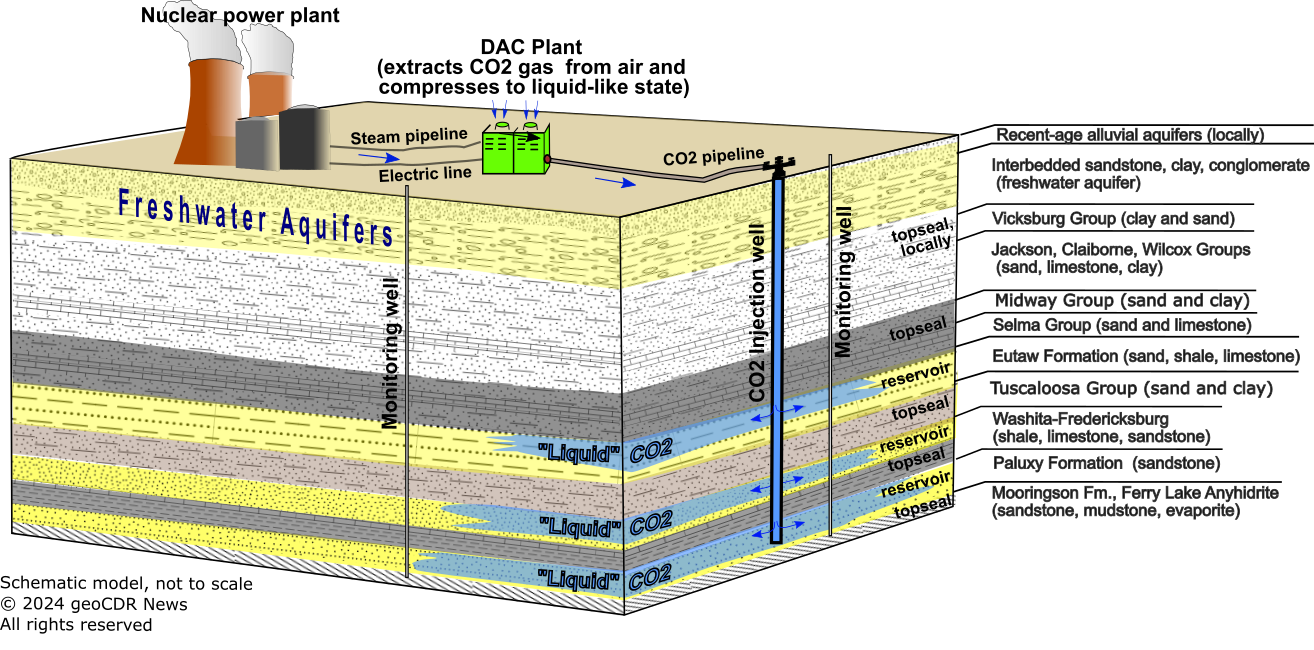

The Farley study included evaluating the feasibility of permanent underground storage of CO2 that the DAC plant captures. The semi-liquid CO2 would most likely be transported by pipeline to an injection well located outside the Farley site where the CO2 would be injected underground for permanent storage in porous layers of sedimentary rocks.

The block diagram below shows geoCDR News' conceptualization of underground CO2 storage at the Farley site.

A Battelle PowerPoint presentation made in August 2024 indicated CO2 storage is likely to be in sandstone layers of Cretaceous age: the Eutaw Formation, Washita-Fredericksburg Group, and Paluxy Formation. These reservoir rocks lie more than 800 meters below the land surface.

Low- shale and sandstone layers overlie each reservoir layer, providing a "" (caprock) above each reservoir. Freshwater aquifers are near the land surface, more than 700 meters above the reservoir layers.

The August 2024 Battelle presentation indicated that, at the 50% probability level, more than 70 million tonnes of CO2 can be stored in each of the reservoir units — far more than the 5,000 tonnes of CO2 captured annually by the pilot-scale DAC plant evaluated in the study. The estimate was for a geographic area extending out about 40 km from one side of the nuclear power plant site.